Article Innovation and the Future of the IT Supply Chain

By Jamie Werve / 18 Jun 2020 / Topics: IT optimization , Featured , Procurement

The term “digital transformation” is everywhere. In fact, for the last several years, there’s been a lot of discussion in the IT space about the need to transform business for the future.

Until recently, “the future” may have seemed like a fairly vague concept. It was something businesses felt they had plenty of time to prepare for themselves. But if 2020 has taught us anything so far, it’s that “the future” is here. The time to transform is now.

The real question is: How do you make digital transformation a reality?

Right now, companies are struggling to, as my team likes to put it, “keep the lights on.” In other words, they’re zoned in on the day-to-day operations that keep the business running. And when day-to-day operations take up most of your time and most of your budget, how can you possibly focus on — or invest in — anything else?

The truth is, in order to focus on digital transformation projects, businesses must first look at how to innovate within their existing IT supply chains.

A different kind of innovation

When you imagine IT innovation, you probably think of concepts like smart cities, connected devices, groundbreaking applications and so on. But innovation doesn’t just mean artificial intelligence or the Internet of Things (IoT).

When it comes to IT supply chains, innovation means embracing concepts like consolidation, automation and integration. It means streamlining traditional, manual and clunky processes. It means bringing these technologies into the 21st century.

Embracing automation

There are huge opportunities for companies to leverage the power of automation in their IT supply chains.

There are still a lot of businesses out there that employ almost entirely manual procurement processes. Employees are still forced to create a physical purchase order, then track down the correct approval person for a signature. If they’ve asked for a brand or style of product that’s not approved by the business, they’re forced to go back and start from the beginning.

That’s a lot of time and a lot of effort just to get the right product on the purchase order. Then the company has to go through the next series of steps, such as verifying that the employee has business justification and that all the appropriate data elements are included in the order.

With the technology available today, this process could be entirely automated. Instead of creating orders by hand, the employee could be going to a customized e-procurement portal where they see only pre-approved products and can put in an order with a few clicks of their mouse.

Imagine the time saved (and by extension, the costs cut) by removing all that back-and-forth from the process. Imagine knowing, from the beginning, your employees will only be able to order pre-approved products. Imagine approvals for that order being automatically routed to the correct approver.

Even within the simple workstream of buying a new piece of hardware, getting an invoice and knowing who to charge back internally, there’s a tremendous amount of opportunity for companies to increase their efficiency.

Data. Data. Data.

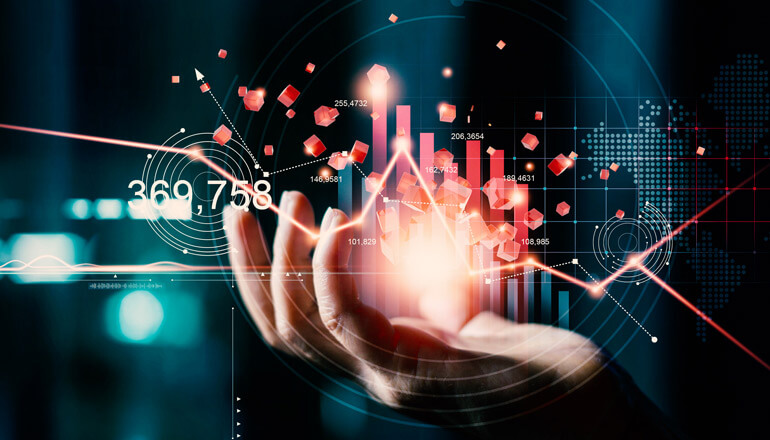

Data is probably the biggest pain point for businesses right now.

And it’s not just about getting the right kind of data, it’s about having the ability to synthesize that data and build meaningful views in order to make informed business decisions. It’s also often not just about finding ways to optimize. Many businesses struggle with simply understanding the current state of their environment.

Innovating within the IT supply chain hinges on a business’s ability to see all their data. And it’s imperative that this data is in the right place at the right time so decision-makers can look at it from every angle and make the right decisions about the future of the business.

Data is probably the biggest pain point for businesses right now.

Effective integration

Many businesses are already invested in tools meant to help make purchasing more automated or asset management easier. The problem is that these tools aren’t often synced into one, cohesive system.

Add in the aforementioned difficulties with getting the right data in the right place at the right time, and you’ve got a serious problem. When trying to make data-driven decisions, disparate systems only serve to muddy the waters.

Proper integration gives businesses the ability to get all the data points they need to make effective business decisions. To achieve this integration, companies should lean on a knowledgeable partner that will take a deliberate approach to integration. If there’s one thing that’s worse than incongruent systems, it’s a hastily stood up solution that’s faulty at best. Which leads me to my final point.

The importance of vendor consolidation

To achieve the optimization and automation that businesses desire — and, frankly, need — they have to consolidate vendors.

When trying to take a thoughtful approach to integration or introduce less manual processes, companies simply can’t afford to have vendor sprawl. They need a deeper level partnership and an expansive portfolio of technology solutions in order to be successful in their transformation.

When vetting potential IT partners, focus on finding an organization with the capabilities to help you not only achieve today’s goals, but also the ability to scale with your business as it grows.

It’s equally as important to find a partner that takes the time to understand your business driver and what you’re trying to achieve. Anyone can come in and install another expensive tool. You need a partner that thoughtfully designs solutions with your end goal in mind.

That’s why Insight coined the term “super solution integrator.” This new breed of IT partner doesn’t just consult on the right solutions and bring order to disparate systems. We’re innovation experts who can manage the entire digital transformation process from end to end.

To achieve the optimization and automation that businesses desire — and, frankly, need — they have to consolidate vendors.

The power of supply chain innovation

The idea of an optimized supply chain isn’t a new concept. But the time to transform business is here — companies simply can’t afford to wait anymore.

But innovation doesn’t only mean cutting-edge technology. In the case of IT supply chains, innovation means streamlining processes, integrating systems, leveraging data and utilizing the right kind of partner.

And the power of an innovative supply chain is incredible. Optimizing this part of the business helps cut costs and increase efficiency so companies can focus on other digital transformation projects.

It’s time to get started. Supply chain innovation is a business necessity and Insight can help you get to an optimized state. We help our clients cut time and costs out of their procurement processes, simplify product lifecycle management and maximize software investments. Click here to read more on what we do in the supply chain space.

About the Authors:

Related articles

Narrow your topic:

Procurement Supply Chain Optimization Enterprise Tech Journal View all focus areas