Listicle text included for screen readers:

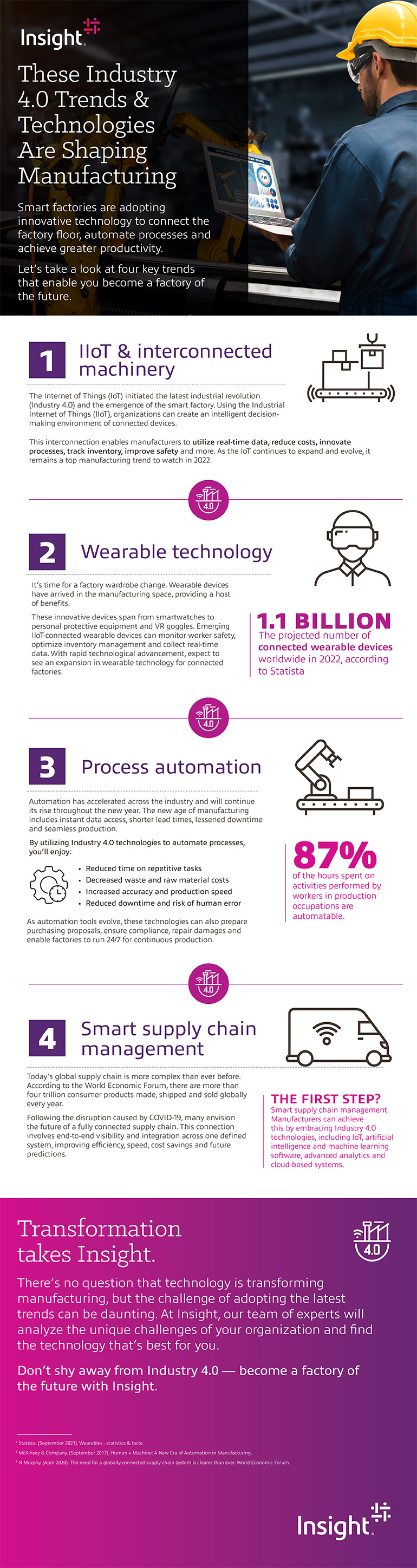

Smart factories are adopting innovative technology to connect the factory floor, automate processes and achieve greater productivity.

Let’s take a look at four key trends that enable you become a factory of the future.

1. IIoT & interconnected machinery

The Internet of Things (IoT) initiated the latest industrial revolution (Industry 4.0) and the emergence of the smart factory. Using the Industrial Internet of Things (IIoT), organizations can create an intelligent decision-making environment of connected devices.

This interconnection enables manufacturers to utilize real-time data, reduce costs, innovate processes, track inventory, improve safety and more. As the IIoT continues to expand and evolve, it remains a top manufacturing trend to watch in 2022.

2. Wearable technology

It’s time for a factory wardrobe change. Wearable devices have arrived in the manufacturing space, providing a host of benefits.

These innovative devices span from smartwatches to personal protective equipment and VR goggles. Emerging IIOT-connected wearable devices are able to monitor worker safety, optimize inventory management and collect real-time data. With rapid technological advancement, expect to see an expansion in wearable technology for connected factories.

According to Statista, the number of connected wearable devices worldwide will rise to 1.1 billion in 2022.

3. Process automation

Automation has accelerated across the industry and will continue its rise throughout the new year. The new age of manufacturing includes instant data access, shorter lead times, lessened downtime and seamless production.

By utilizing Industry 4.0 technologies to automate processes, you’ll enjoy:

- Reduced time on repetitive tasks

- Decreased waste and raw material costs

- Increased accuracy and production speed

- Reduced downtime and risk of human error

As automation tools evolve, these technologies can also prepare purchasing proposals, ensure compliance, repair damages and enable factories to run 24/7 for continuous production.

87% of the hours spent on activities performed by workers in production occupations

are automatable.

4. Smart supply chain management

Today’s global supply chain is more complex than ever before. According to the World Economic Forum, there are more than four trillion consumer products made, shipped and sold globally every year.

Following the disruption caused by COVID-19, many envision the future of a fully connected supply chain. This connection involves end-to-end visibility and integration across one defined system, improving efficiency, speed, cost-savings and future predictions.

The first step? Smart supply chain management. Manufacturers can achieve this by embracing Industry 4.0 technologies, including IoT, artificial intelligence and machine learning software, advanced analytics and cloud-based systems.

Transformation takes Insight.

There’s no question that technology is transforming manufacturing, but the challenge of adopting latest trends can be daunting. At Insight, our team of experts will analyze the unique challenges of your organization and find the technology right for you.

Don’t shy away from Industry 4.0 — become a factory of the future with Insight.

References:

1 Statista. (September 2021). Wearables - statistics & facts.

2 McKinsey & Company. (September 2017). Human + Machine: A New Era of Automation in Manufacturing.

3 N Murphy. (April 2020). The need for a globally-connected supply chain system is clearer than ever. World Economic Forum.